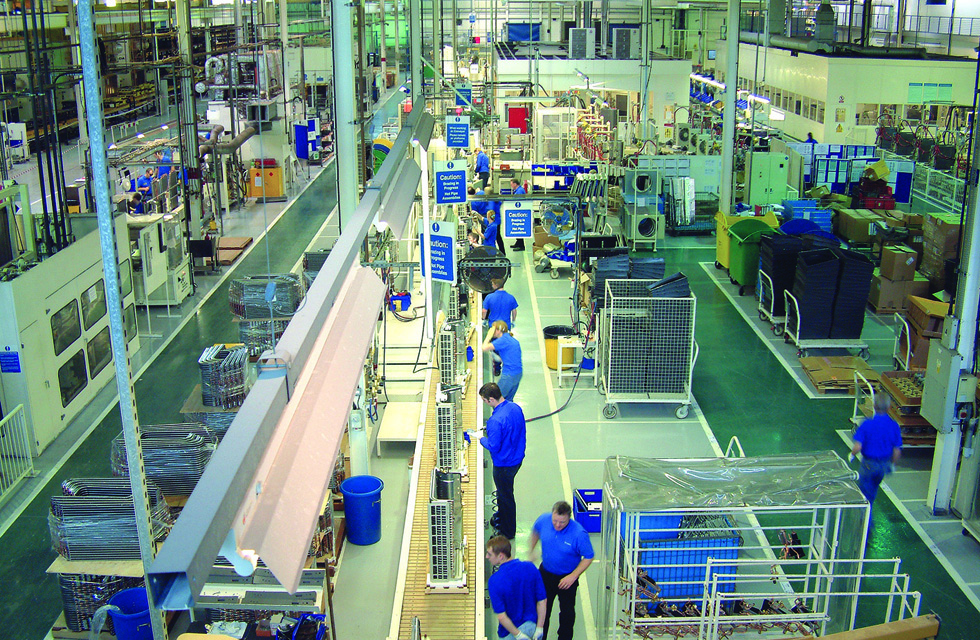

I spent a day last week travelling up to Scotland as a guest of Mitsubishi Electric as I visited their manufacturing plant in Livingston to attend the press launch of their new Ecodan air source heat pump. And I have to say, I was impressed.

Not only had the organisers made the whole thing easy (apart from the early start!), the staff at the factory could not have been more accommodating and the facilities there are seriously impressive.

Mitsubishi Electric has been manufacturing air conditioning there since the late 1980s and heat pumps for the past decade.

They have invested significantly in testing facilities and have even built two identical 3-bed semi-detached houses in their car park where they test a gas boiler against an air source heat pump.

I for one definitely think the company is on to a winner!

Keep the noise down

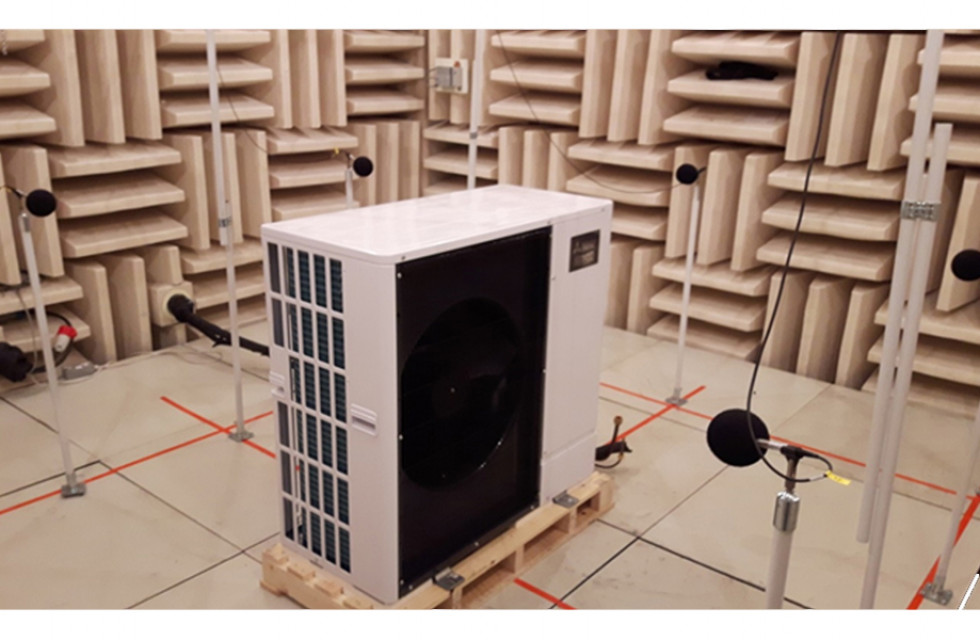

One of the areas we were lucky enough to be shown was the factory’s anechoic chamber, where noise levels of the units are tested.

We heard the noise differences between the current 8.5kW Ecodan (which is very quiet) and the new model (which is almost silent).

The reason noise is important in this context is that Mitsubishi Electric’s latest Ecodan air source heat pump is claimed to be one of the quietest available on the market.

The Ecodan brand has led the market over the past decade in terms of noise levels and performance, and these new models take this to a new level to offer complete flexibility on where the outdoor unit can be sited.

“The government has already recognised how important air source heat pumps will be for the future of low carbon heating in the UK and is forecasting one million sales a year by 2030,” says Max Halliwell, Product Manager for the company’s renewable heating systems, who explained the system to the visiting journalists.

“One of the key areas that will affect adoption of these energy-saving systems is noise which is why permitted development exists and these new units are designed specifically to overcome any issues with noise,” he added.

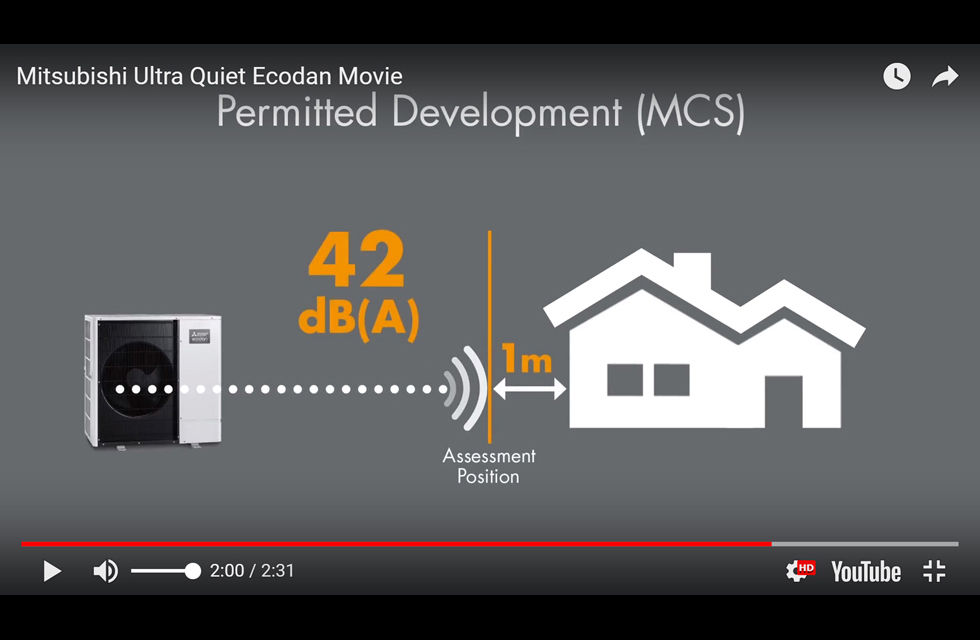

In the residential environment, sound is important because low sound increases the flexibility of where a heat pump can be positioned.

To ensure neighbours aren’t disturbed, Permitted Development requires sound levels to meet certain limitations, with the sound pressure level not exceeding 42 decibels, dB(A) when measured at a point one metre away from the neighbour’s nearest door or window.

Sound matters

The Ultra Quiet Ecodan air source heat pumps are available in 8.5kW and 11.2kW sizes with sound levels that are three times quieter than previous models, virtually eliminating planning restrictions.

Designed specifically for residential applications, these models offer superb, market-leading energy efficiency and sound levels and enable almost any home to benefit from high performance, renewable heating.

“Our market leading Ecodan heat pumps have always been amongst the quietest on the market and are designed to provide any home with reliable, trouble-free renewable heating and hot water,” adds Halliwell.

“New Ultra Quiet Ecodan takes this to the next level with low sound and high performance which mean homeowners can now choose the most convenient location for their heat pump, giving complete flexibility on placement and still meeting Permitted Development requirements.”

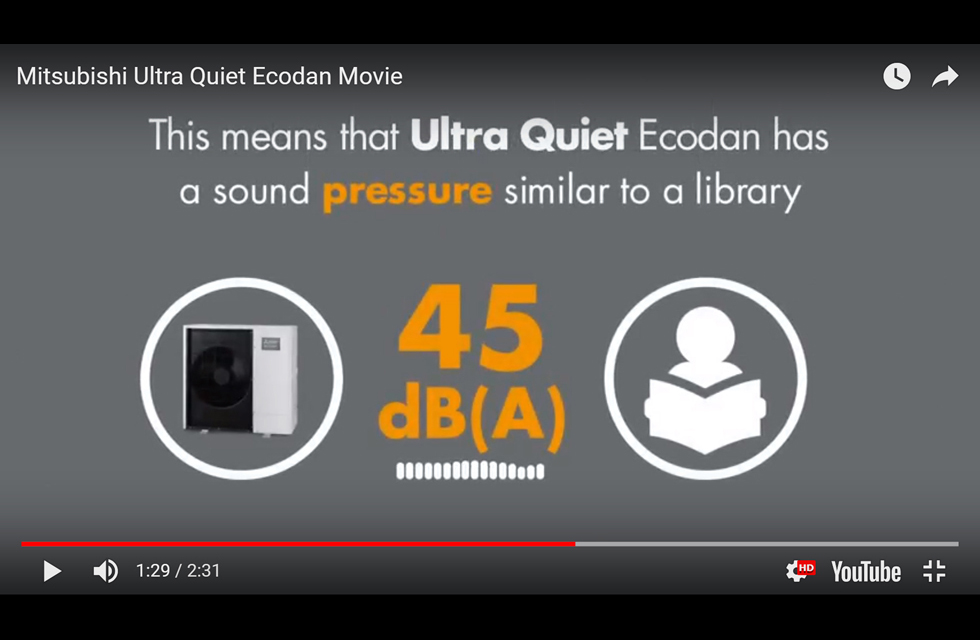

The 8.5kW Ultra Quiet Ecodan has a sound power level of only 58 dB(A) which is an 8 dB(A) drop over the model it replaces. It also has a sound pressure level of just 45 dB(A) at one metre

How we receive sound

Sound power can be thought of as the cause of a noise or the total sound energy emitted by a source in all directions, whereas sound pressure is the effect or the sound we hear and this is determined by the environment and by the distance from the source of sound.

We think of this as the intensity or loudness of a sound. An ambulance registers 120 dB(A) whereas a vacuum cleaner registers around 73 dB(A) and typical room conversation comes in at around 60 dB(A).

“With a sound pressure level of just 45 dB(A), the new Ecodan is whisper-quiet, with levels just above that of a library, meaning it will pass the Permitted Development requirements easily and can be installed almost anywhere to suit the homeowner,” explains Halliwell.

“This is a result of a decade of manufacturing Ecodan in Scotland and we have used this knowledge and experience to refine Ecodan and design it specifically for UK residential use.”

And the facilities at the Livingston plant are certainly impressive.

Serious investment

Mitsubishi Electric has invested significantly on the site. They not only have a dedicated anechoic chamber to measure sound levels and a room where they can drop temperatures down to -30ºC to measure performance, but as mentioned, they have actually built two identical houses in the car park to put the units to test in a domestic setting.

One house uses traditional gas heating whilst the other uses an Ecodan unit and R&D staff monitor the hundreds of detectors in the two buildings to help develop and refine the product range even further.

This has led to innovations in fan and compressor design for the new models which has enabled the units to achieve such low levels of sound whilst increasing performance and efficiency.

Both models in the range (PUHZ-W85VAA and PUHZ-112VAA) are both A++ ErP rated and also available with coastal protection for areas where they can be exposed to saline.

If the government’s predictions of residential heating being dominated by air source heat pumps over the next decade are correct, then Mitsubishi Electric’s dedicated investment in manufacturing in Britain for Britain will have paid off.

Regardless of this, anyone using a renewable heat pump will want complete reliability and low noise levels so I for one definitely think the company is on to a winner!

Further details on the performance of the units including a short animation on the importance of sound levels in achieving Permitted Development can be found at the dedicated website.

Carole Titmuss is editor of Refurb Projects magazine