What is our recycling programme?

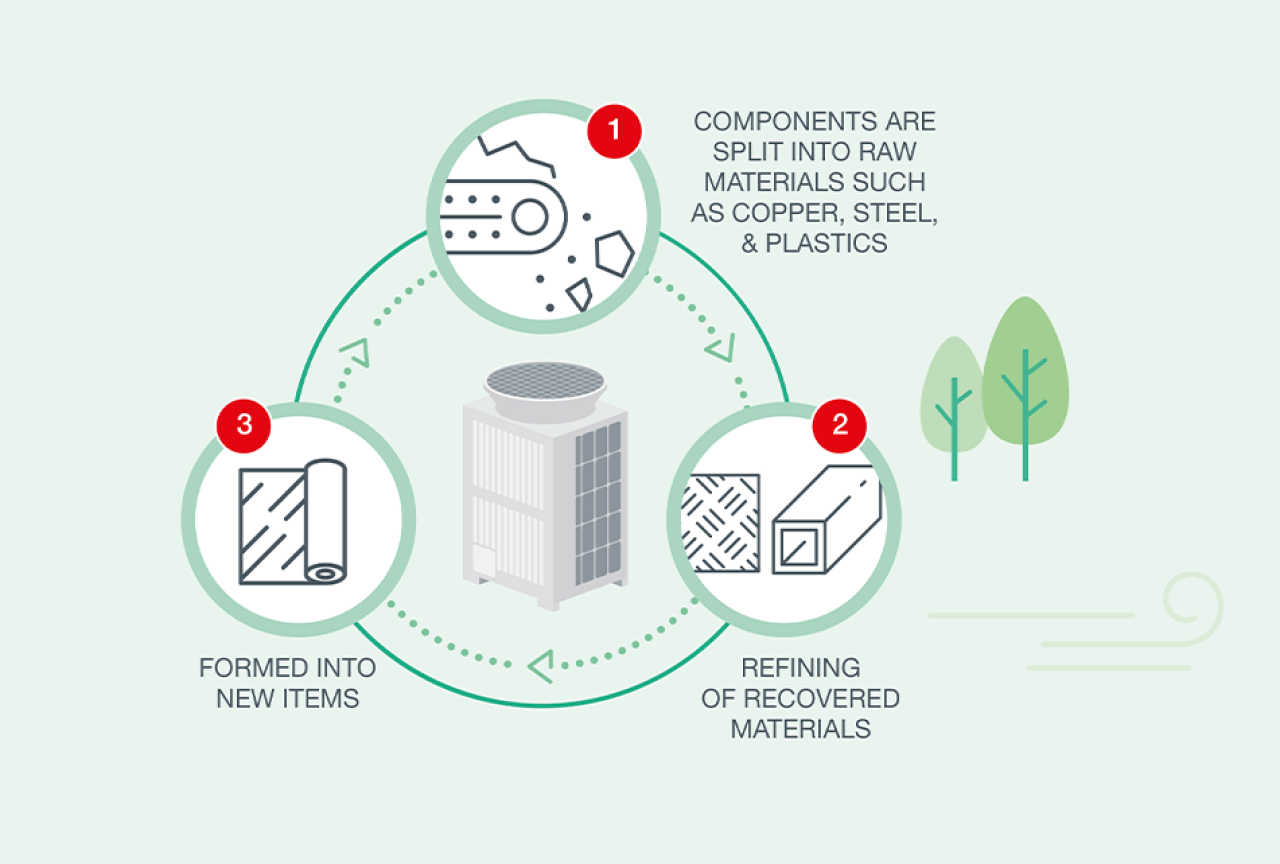

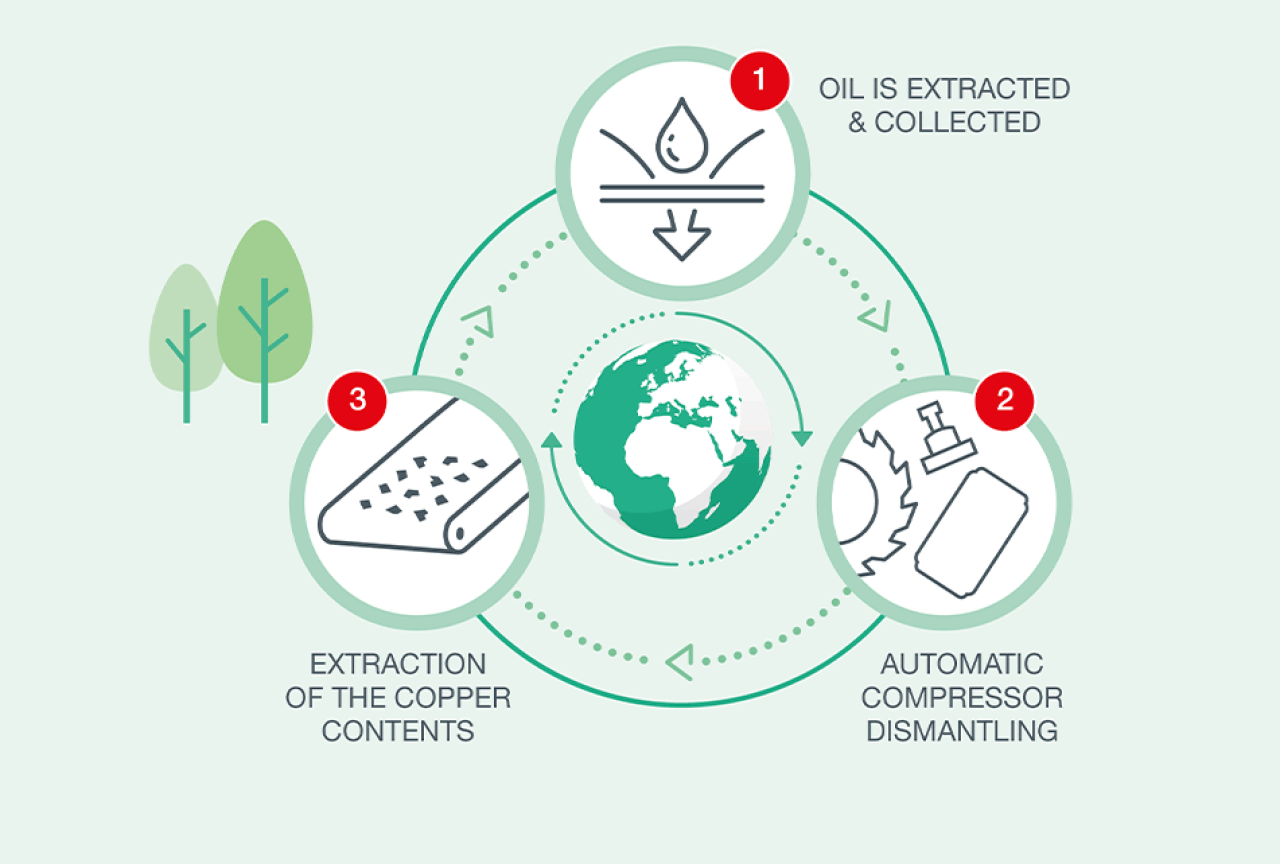

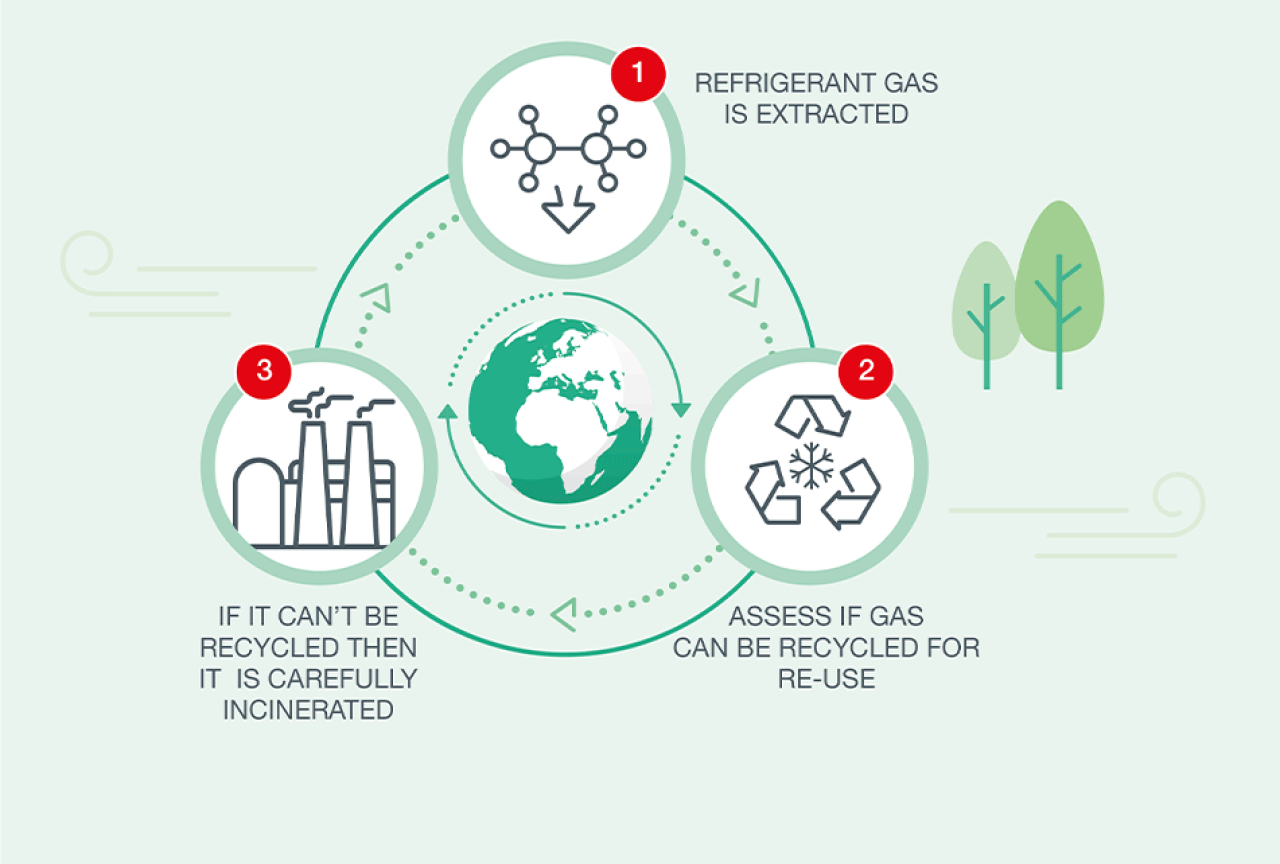

Our mission is to provide solutions that deliver what building occupants need, while reducing the environmental impacts as much as possible. We have developed our HVAC end of life cycle service to help mitigate the environmental impact of old HVAC equipment by ensuring that defunct air conditioning units are dismantled in a compliant manner, in line with current legislation, and that the materials are reclaimed for use elsewhere, minimising the strain on natural resources.