All buildings have a continuous requirement for heating, not only for keeping occupants warm in the colder months, but also for the year-round supply of domestic hot water services.

How you deliver that heat to a building is now under scrutiny as never before, with ambitious carbon reduction targets meaning building operators face tougher legislation than ever.

At the same time, we have seen a ‘greening’ of the national grid with increased electricity generated from renewable sources and this is where electrically-driven systems that can recover heat and reuse it are now coming to the fore as our recent CPD-accredited webinar on heat recovery chillers clearly demonstrated. [Link to sign up]

What this all means for building owners and operators is that there is a real opportunity to maximise the efficiency of HVAC plant AND lower both carbon emissions and running costs, by finding and reusing wasted heating within their buildings.

Heat recovery is the next big win for cutting emissions in commercial buildings

Heating now top of the agenda

Through the Committee on Climate Change (CCC), the government has recently announced that the decarbonisation of the UK’s heat production is a primary objective over the next five to ten years.

The residential sector will be an early focus and we are likely to see calls for greater improvements in the efficiency of existing homes than was achieved through previous ‘loft insulation-type’ initiatives.

At the same time, commercial buildings will have to be included in the programme otherwise we simply will not achieve our carbon reduction targets.

Building owners and facilities managers already face a number of regulations and laws which are already driving heating to the top of the environmental and business agenda.

In particular, the shift from fossil fuels to electricity as the primary source of energy in buildings will see the end of gas in our major towns and cities.

Add to this the benefits of using inverter-driven chillers, air conditioning and heat pumps, and we now have a perfect mix of viable and affordable solutions.

So where are the answers?

While low-carbon heating options such as heating-only air source heat pumps are available for buildings, they often occupy a larger footprint that traditional systems. This makes them challenging to utilise for many urban new-builds and refurbishments where space for plant is a serious consideration.

Inner city applications are using much more compact HVAC solutions, where larger renewable solutions may be impractical simply for reasons of space availability.

An alternative may be to consider heat recovery systems that can be included in the HVAC plan with little to no impact on space requirements.

Even the addition of a small heat recovery system supplementing larger plant can have a dramatic impact, reducing energy consumption and carbon emissions.

We are seeing increasing interest is the application of heat recovery systems for one simple reason – you can make significant savings in energy use, without the need for additional equipment.

This is because re-using heat that has already been generated in the building (for example, when rejected from the cooling system), means you can save on the energy you would otherwise need to generate that heat – also helping reduce operational costs in the long-term.

The captured heat can then be applied to various areas of the building. This works particularly well in mixed use projects or large offices, where heat profiles are diverse. Heat can be captured from the cooling process and used to reduce the heating requirements in other areas of the building.

Old versus new thinking

Significant benefits

Save money and reduce emissions

Heat is an often-wasted by-product of cooling in our commercial buildings and, given the growing policy pressures and rising costs, it is simply throwing money away to leave that heat unused.

Adding or capitalising on the heat recovery potential of new or existing equipment is therefore not only a commercially savvy option, it provides a genuine route to reducing a building’s impact on the environment.

For the past decade, government policy has enabled the UK to move to much lower-carbon production of electricity. However, the national carbon reduction targets continue to set new challenges – and for both the nation, and individual businesses, heating is the next big win for cutting emissions.

At the same time, we need to reduce our energy use overall, creating an enormous challenge for building designers and managers.

Different options

In essence, there are three basic ways of undertaking heat recovery: Simple; Partial; and Total.

Simple heat recovery is already at work in the popular VRF systems that have been applied in many projects over the past few years. VRF systems use direct expansion as the heat recovery method and will transfer energy from one part of a building to use elsewhere.

For chilled water applications though, there are a number of solutions and approaches that are available, depending on the particular project requirements. These include Partial and Total heat recovery.

Partial heat recovery from a chiller is great for smaller applications and is an excellent solution for providing domestic hot water (DHW) in a building during the summer months.

Each refrigerant circuit is fitted with a desuperheater in series with the condenser coils. This harnesses the ‘waste’ energy in the form of heat and is ideal for providing hot water at around 60 degrees C.

Total heat recovery is an excellent solution where there is a very large cooling requirement such as in manufacturing processes and IT cooling. The greater the cooling load, the more heat energy there is to collect.

Simultaneous heating and cooling

Large office buildings, shopping centres and hotels are just a few examples of where there are coincidental or simultaneous heating and cooling loads.

IN many modern buildings, it is not unusual to find that one area of a building requires cooling whiles another needs heating. This can be due to the orientation of the building, solar gain, shading and other factors.

And in mixed-use developments, perhaps combining offices, dwellings and retail facilities, the requirements for heating and hot water will vary throughout the day – as will occupancy and times of peak demand.

This is an ideal environment in which to remove heat of rejection from an office that requires cooling, for example and use it to provide heating or hot water for residential areas, or perhaps to supplement hot water.

Competing systems

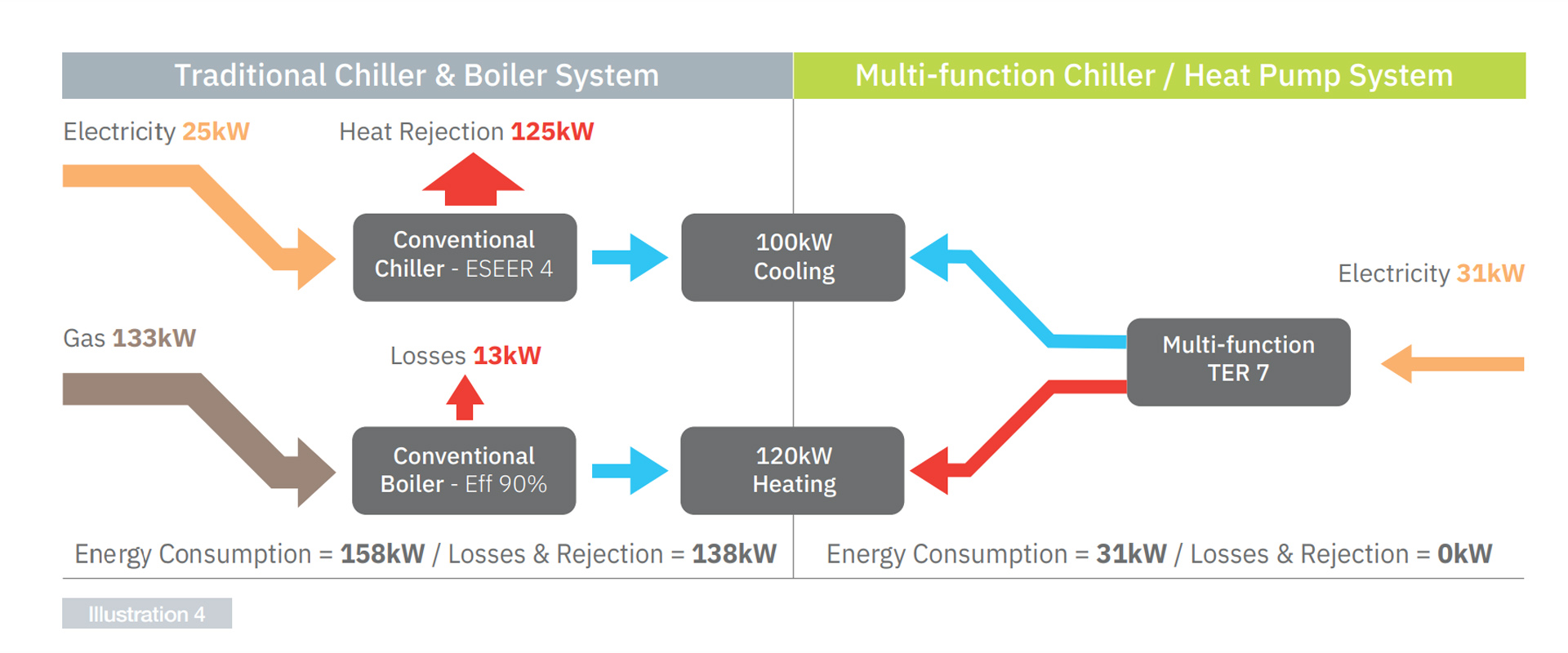

The traditional approach to the challenge of providing heating and cooling simultaneously has been to use a gas boiler and a chiller. These are two systems that do not work together, one burning gas to generate heat, while the other chills water by releasing heat energy to the atmosphere.

However, an alternative approach, particularly for those looking to move away from the use of gas as a heat source towards cleaner electricity, is to use a chiller with simultaneous heating.

The first benefit is reduced capital cost, as there is no boiler to install and no gas connection required. Long-term operating costs have also been shown to be significantly lower than the chiller-boiler combination, with up to 40% energy savings.

There are several detailed examples in the CPD Webinar, which can be viewed at the following link

To summarise the potential though, systems already exist that can help businesses to harness what is otherwise wasted energy to save money.

By capturing generated heat rejected from elsewhere and re-applying it within the building, you can reduce the energy needed for heating lowering overall consumption and emissions.

These systems also offer space saving over traditional solutions, are easier to design and install, and are ideal for inner-city projects and mixed-use developments where one element will require cooling (e.g. Kitchens, gyms, IT cooling) and others will require heating (e.g. hot water for apartments).

Simultaneously benefiting both the environment and the bottom line!

Richard Venga is Business Planning and Strategy Manager for Central Plant