Did you know that we collect old HVAC and take it away to be recycled?

All the engineers I meet each month realise the important role that the HVAC industry plays in reducing energy use and carbon emissions.

Yet many aren’t aware of the comprehensive recycling scheme that will collect and recycle old HVAC equipment. Not only can this help installers remove waste from site, but it also ensures as much material is recovered as possible.

We’ve developed a recycling programme for end-of-life air-conditioning units and heating units. In partnership with Environcom this gives installers an easy to use and certificated route for disposal of end-of-life equipment.

This is all done in the UK, reducing the need to send anything overseas for recycling.

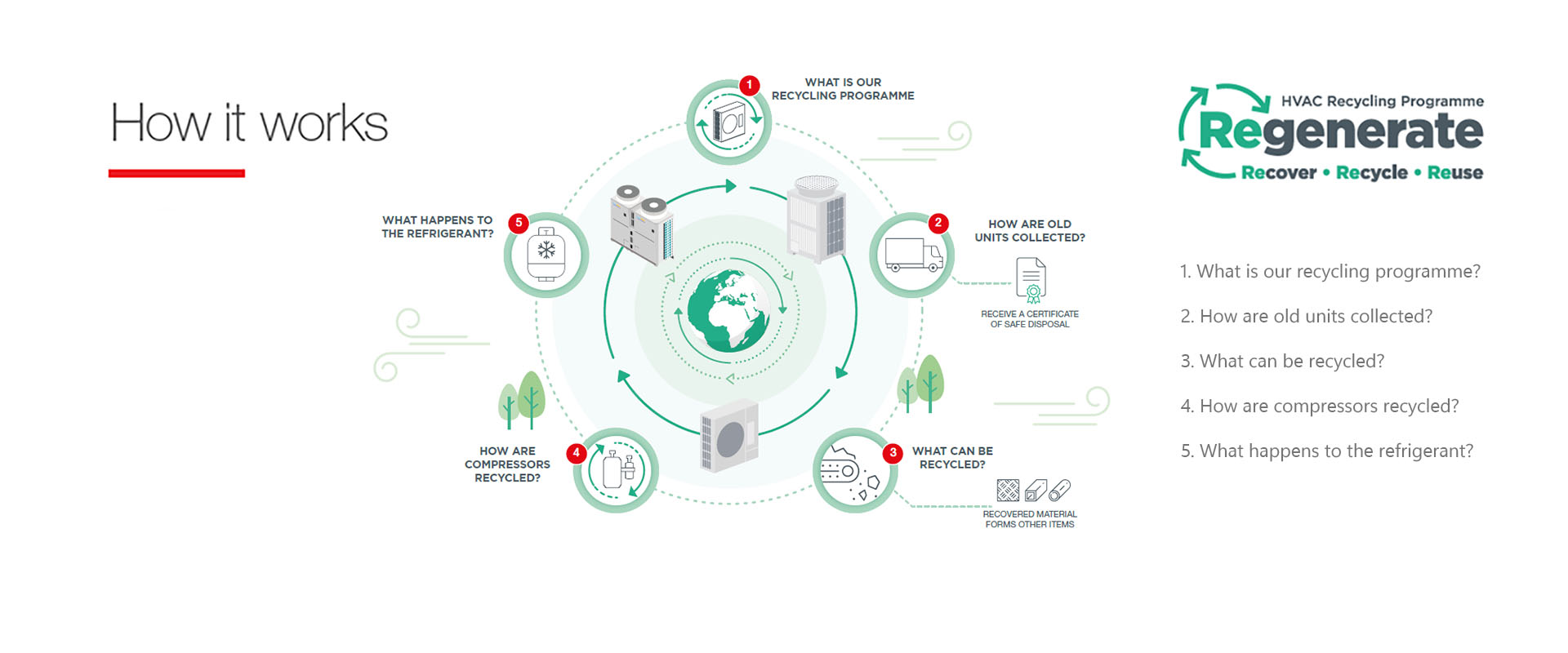

1. What is our recycling programme?

We want to help installers provide solutions that deliver what building occupants need, while reducing the environmental impacts as much as possible, so we developed this service to help mitigate the environmental impact of end-of-life HVAC equipment.

By ensuring that old or defunct air conditioning units are dismantled in a compliant manner, in line with current legislation, then these materials can be reclaimed for use elsewhere, minimising the strain on natural resources.

2. How are old units collected?

The Environcom recycling programme sits alongside their exisiting E Waste Recycling and Reuse Services, which delivers a certificate of safe disposal of old equipment.

Any installer that is a member of our Partner Programme can use their Relationship Development Fund (RDF) to pay for the collection*.

To arrange a collection our customers can simply contact Environcom on 0844 736 0071 or email Customer.service@environcom.co.uk stating that they are a Mitsubishi Electric customer.

Recycling

Recovering materials from end-of-life equipment

3. What can be recycled

We are all responsible for using and re-using our finite recourses. Recovering and recycling our used materials is more important than ever. It is estimated that 98% of materials from old HVAC equipment can be recycled.

What happens to the different materials? Well 80% of recycled plastics are of a quality that can be used to manufacture new products, such as automotive parts, or in building and civil engineering materials. The remaining 20% are used for thermal recycling.

Mitsubishi Electric air conditioners use about 10% recycled plastic. Other materials recovered such as iron, copper, and aluminum are 100% recycled. These are taken over by professional contractors and reused as raw materials.

Other rare earth materials, such as Gold, Silver and Neodymium, are also recovered for re-use.

4. How are compressors recycled?

After the refrigerant and oil is extracted and collected, Environcom recycles the compressor using the UK’s first automatic compressor dismantling machine.

CARRiE (Compressor Automatic Removal Recycling Equipment) allows the automatic extraction of the copper rich contents from inside the compressors while also separating the steel shell.

This is all done in the UK, reducing the need to send anything overseas for recycling.

5. What happens to the refrigerant?

Refrigerants can harm the ozone layer and contribute to global warming if released, so the safe extraction and handling of refrigerants is a top priority.

When decommissioning old HVAC equipment, the contractor will need to extract any refrigerant gas from a system into a cylinder, this process is called ‘degassing’ (reclaiming). The contractor then takes the collected gas to their refrigerant processor for handling.

The refrigerant processor analyses the gas to assess whether it can be re-used, blended with another refrigerant for re-use or needs to be destroyed due to its chemical composition.

The process offered by Environcom allows for refrigerant that remains in the end-of-life unit to be safely handled and not allowed to be released to atmosphere.

Any residual refrigerant in the redundant HVAC unit is safely removed at Environcom and processed on site through Geri (Gas Energy Recovery Incinerator), which ensures these gases are destroyed by high temperature incineration. Geri can also supply hot water and heating to be used in the plant.

If you would like to know more about the recycling programme please visit our website.

Ben Bartle-Ross is a Technical Trainer at Mitsubishi Electric