Many of the world’s largest manufacturers are setting environmental targets across their organisations, to play their part in reducing global warming.

As a result, they are paying closer attention to refrigerants in their buildings’ cooling and heating systems.

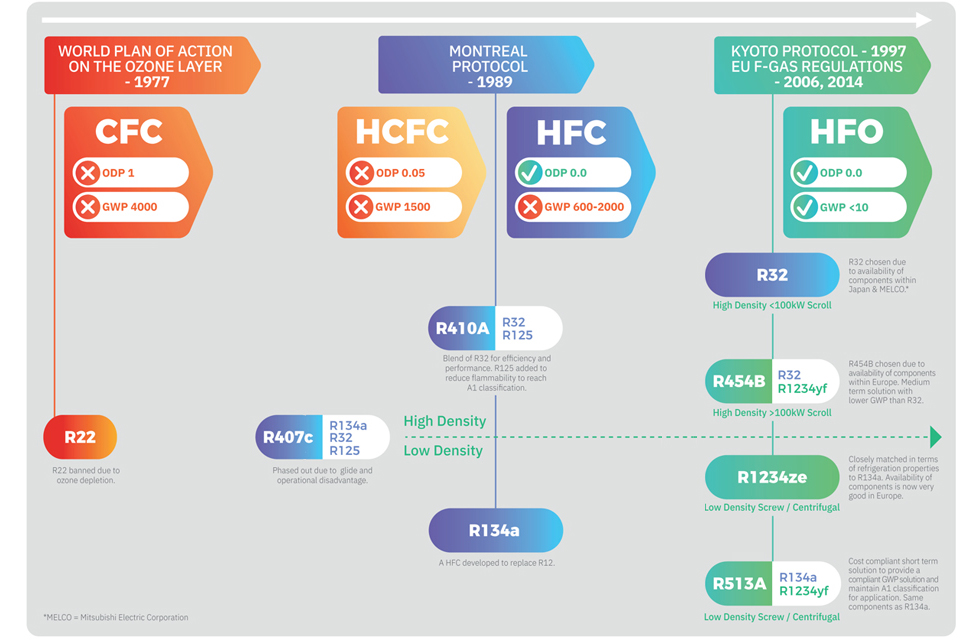

Regulations are also forcing a change in the use of refrigerants.

The F Gas Directive is driving down the global warming potential (GWP) allowed in refrigerants for these systems.

Not only does this mean that options are changing right now, but building and operations managers have to consider what happens in the future as refrigerants are phased down.

The implications for refrigerant choice become much more weighted.

The move to R32

The ability to find replacement refrigerant at predictable prices is an essential factor for them to consider. For example, during the phase down process for R410A and R22 service blends, prices increased by 600%.

R32 (with a GWP of 675) is now one of the most popular refrigerants on the market, and Mitsubishi Electric has been offering it as part of our product range for some time and is currently the only manufacture that can offer R32 models from individual room air conditioning right up to VRF.

This include the Hybrid VRF (H-VRF) system, which differs from traditional VRF as it uses water throughout the majority of its pipework instead of refrigerant but is still able to simultaneously heat and cool different rooms.

This use of water removes the need for any leak detection in occupied spaces (required when using R32) and helps lower annual maintenance costs. Hybrid VRF offers high operational efficiency while lowering the global warming potential (GWP) of the system as a whole.

Even lower GWP

Other refrigerants are making their way onto the market, including hydro fluoro olefins (HFOs), such as R1234ze and R1234yf. They have GWPs of 7 and 4 respectively.

Chillers from our Climaveneta brand are already using the R1234ze – and are designed to operate optimally with using the characteristics of this refrigerant.

R1234yf is used in the high-density scroll chiller; and R1234ze low-density screw chiller.

It is essential that where HFOs are used, the equipment is designed around the performance of the refrigerants. R1234ze has zero environmental impact, with a small reduction in chiller capacity. Energy efficiency performance remains the same, but there is an increase in cost. It is also an A2L refrigerant (like R32), categorising it as ‘mildly flammable’.

A blended approach

Blends of refrigerant are also seeing increased use. For example, R454b (GWP 466) is a blend of R1234yf with R32. And R513A (GWP 631) is made up of R1234yf and R134a. Both of these are classed as HFO refrigerants, and used commonly in chiller applications as a low GWP option.

More recently, we introduced a high temperature, hot water Ecodan QAHV heat pump, which uses CO2 as a refrigerant. Carbon dioxide has a GWP of 1, making it one of the very lowest available on the market. The QAHV can provide water between 55oC and 90oC – eliminating the requirement for a boiler.

Towards the future

In the past, it was possible to purchase an air conditioning system without much thought to the refrigerant it was using.

In 2020, we are accelerating along a timeline that will remove common HFCs from the market – so the implications for refrigerant choice become much more weighted.

Understanding how long a refrigerant might be readily available is essential.

But for customers who make public commitments to environmental goals, aiming as low as possible on the GWP scale will also be a significant issue. Specifiers and installers need to know what equipment is available right now that can help clients make the right choices for the long-term.

James Smurthwaite, Business Development Manager