I’ve not long come back from an amazing visit to see our MEHITS factory in Italy, which is just north of Venice.

MEHITS stands for Mitsubishi Electric Hydronics and IT Cooling Systems SPA and we took several valued clients to see some witness testing of our chiller and heat pumps systems, which are manufactured at the site.

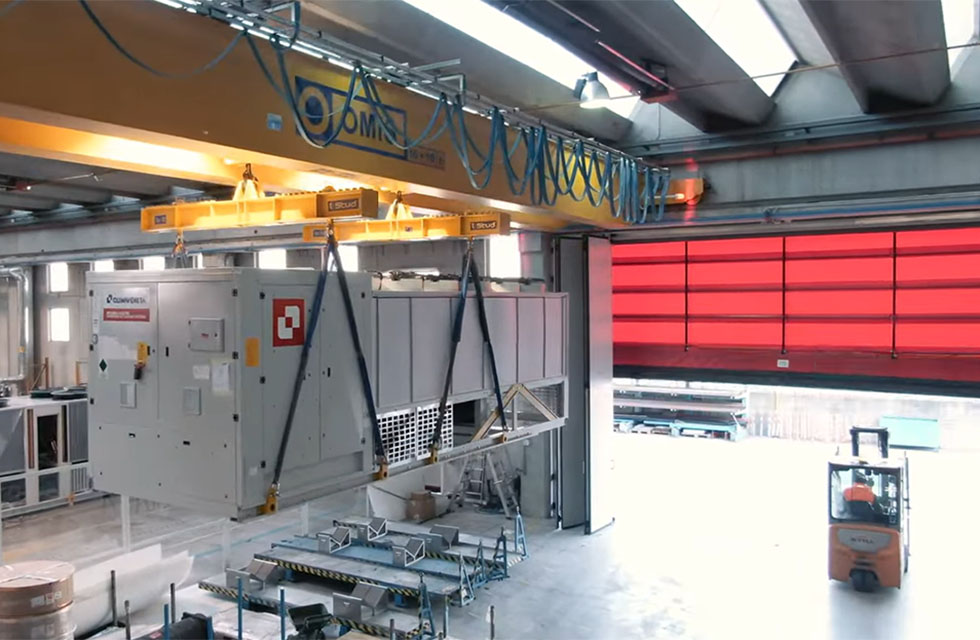

In the world of chillers, witness testing is fairly standard for many customers as each chiller or heat pump system is built for each individual project.

That may mean you have to wait up to 16 weeks for your bespoke system to be built, so a visit to the factory is a way of ensuring that you are getting the quality and performance you expect from your system before it arrives on site.

Engagement with others means we can build the most energy efficient solution for each building

Highest quality

The trip saw us fly out to Venice one Tuesday in November and, following a fantastic meal and restful night in the hotel, we all boarded water taxis and a coach for the 40-minute drive north to Belluno, where the factory is based.

The facility specialises in applied air conditioning solutions for comfort, process and IT Cooling and manufacturers the Climaveneta and RC Group badged products, and now the famous 3-Diamond brand of Mitsubishi Electric, following the acquisition of RC Group and Climaveneta in 2015.

The story of manufacturing in Italy started in 1963 and is one of continuous innovation and the production of high-quality products, which has now been strengthened by becoming part of one of the world’s leaders in air conditioning.

Today, MEHITS is at the forefront of the drive towards a more sustainable society with heat pumps, chillers and IT Cooling systems that comply with, and often exceed, environmental regulations.

We are also launching an increasing number of products on the market with the new green and HFO refrigerants, that offer greatly reduced GWP (Global Warming Potential).

Knowledge-sharing

We took UK customers from several construction companies, M&E Consultants and Consulting Engineers who were able to see the care and quality put into the manufacturing of our applied products, as they toured around the production and testing facilities.

The focus was on heat pump and chiller applications that are going to help with the decarbonisation of the UK's building stock – a major challenge if the nation is going to get anywhere near to net zero by 2050.

As a global manufacturer, our commitment to energy efficiency and sustainability is ongoing and trips like this at the best-in-class Production and Test Facility in Italy give us the opportunity for relaxed and open discussions with our customers.

All in this together

We believe that we build products of the highest quality, yet how these systems are installed and integrated into buildings, and how they are run and maintained during their working life, relies on a host of different skills and professionals.

That’s why it is important to engage with others in the construction industry so that together, we can build the most energy efficient solutions for each project and building.

The visit also gave us plenty of time for site seeing and included a walking tour of Venice and lots of ferry boats and taxis to get us around this ‘floating city’.

All-in-all I found it an amazing trip and great knowledge-sharing experience which helped showcase the added-value we believe is important to offer customers.

Scott Ross is M&E Business Development Manager for Scotland