The air conditioning and refrigeration industries face changes to the types of refrigerants that can be used in the coming years as society looks for ways to reduce the global warming potential (GWP) of equipment.

GWP is measured against a base of carbon dioxide, which is given a GWP of 1.

From 1st January 2020 the use of refrigerant gases with a GWP greater than 2,500 for service will be prohibited for systems which contain more than 40 tonnes CO2 equivalent (although recycled or reclaimed refrigerant can be used until January 2030).

The most common gas affected by this ban is R404A which has a GWP of 3,922. A charge of 10.2kg R404A is equivalent to 40 tonnes CO2, so a continued focus on refrigerant containment is paramount.

Mitsubishi Electric’s latest City Multi R32 YXM VRF system comes with a 30-year lifespan on its BS EN378 compliant low-level leak detectors, compared to the industry average of 10 years.

Under F-Gas rules, systems require a mandatory leak test

Leak detection

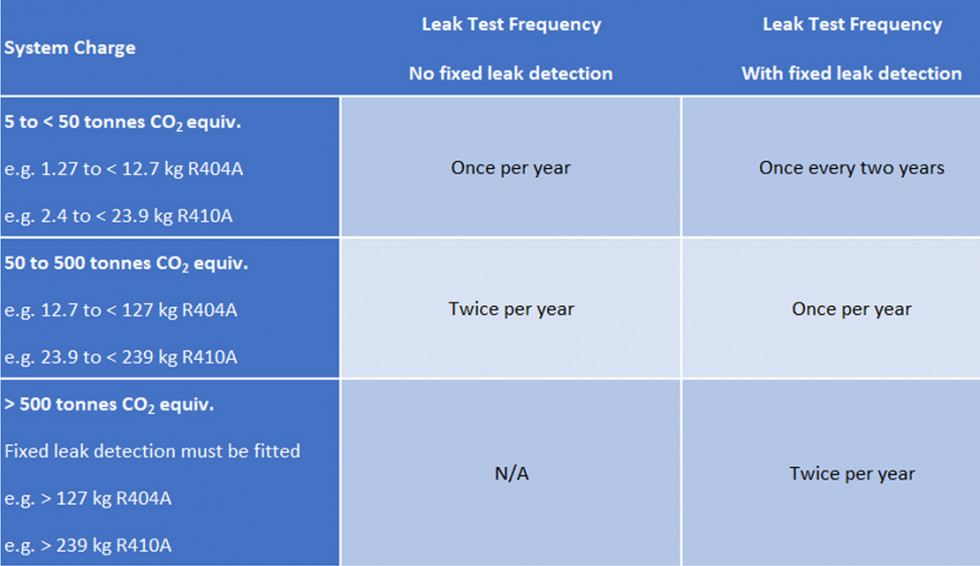

Additionally, under F-Gas rules, systems require a mandatory leak test according to their size (system charge), and whether a fixed leak detection system is in place.

Examples are given in the table below:

Three methods

There are three methods of leak detection; Indirect; Direct and Fixed, and these should form part of the F-Gas log.

The log, which must be kept for 5 years by the operator of the equipment, and the company that services the system must show;

- Quantity and type of F-Gas in the equipment when it’s installed, and when any is added during maintenance (e.g. repairing a leak)

- Details (name, address and certificate number) of any companies that install, service or decommission the equipment

- Dates and results of all mandatory leak checks

- Measures taken to recover and dispose of F-Gases when the equipment is being disposed of (i.e. through a registered waste carrier)

- Whether the gas has been recycled or reclaimed, including details of the recycling / reclamation facility (name, address and certification number), and quantity of gas recovered

Indirect

Indirect methods are generally based on measuring unusual system performance, without breaking into the refrigerant system or circuit. The following items could indicate a leak / loss of refrigerant, and whilst they could also indicate other system issues, they should be followed up with a direct leak check to verify if a leak has occurred, and then identify the source of the leak

- System not achieving capacity / room over temperature

- Bubbling in the liquid line sight glass

- Suction Pressure drop

- Compressor running excessively

- Visual Indications such as oil stains

- Changes in superheat / subcooling compared to normal operating conditions

- Low liquid level in the liquid receiver / low level receiver alarm

- Abnormal noise, vibration or ice formation

Direct

The following are methods:

- Hand held leak detector

- Bubble solution

- Tracer dyes with UV lamp

Fixed

These are fixed, permanently based systems where sensors are placed to detect a leak, which then alert the operator or a service company that a leak is taking place.

Systems containing 500 tonnes CO2e or more of HFC refrigerant must be fitted with fixed leak detection

Final thoughts

It must be noted that with all the above methods, if a leak is found it must be fixed without undue delay and the system re-tested at the point of repair, within one month.

Prevention of leakage points in the first instance would help containment considerably, and also increase the lifetime expectancy, and energy performance of the plant, and all new systems should be designed according to BS EN378:2016, the Safety and Environmental Standard for Refrigeration, Air Conditioning and Heat Pump Systems

For help and advice on all the above, you are always welcome to contact TF Solutions.

Andy Reed is Commercial Director for TF Solutions, the wholesaler and distributor of air conditioning and refrigeration equipment