Like many good ideas in engineering, heat networks aren’t new. They have a venerable, 200-year history of providing heating and hot water to communities around the world. Now, as the UK looks for ways to decarbonise heating and hot water provision in buildings, heat networks are set to be an important solution, as James Chaplen.discovers.

The Climate Change Committee believes that by 2050, heat networks could supply 42% of the heat and hot water in UK buildings, second only to its 52% target for heat pumps. Currently heat networks supply 2% of heat in buildings, so we have plenty of ground to cover.

However, work has already begun. The government’s Heat Network Pipeline Tracker shows a growing number of heat networks are planned in cities across the country.

Funding is also being offered, with over £330 million in the form of the Green Heat Network Fund and Heat Network Investment Project (HNIP).

Temperatures are much lower in a 5th generation network: between 10oC and 30oC.

A history of heat networks

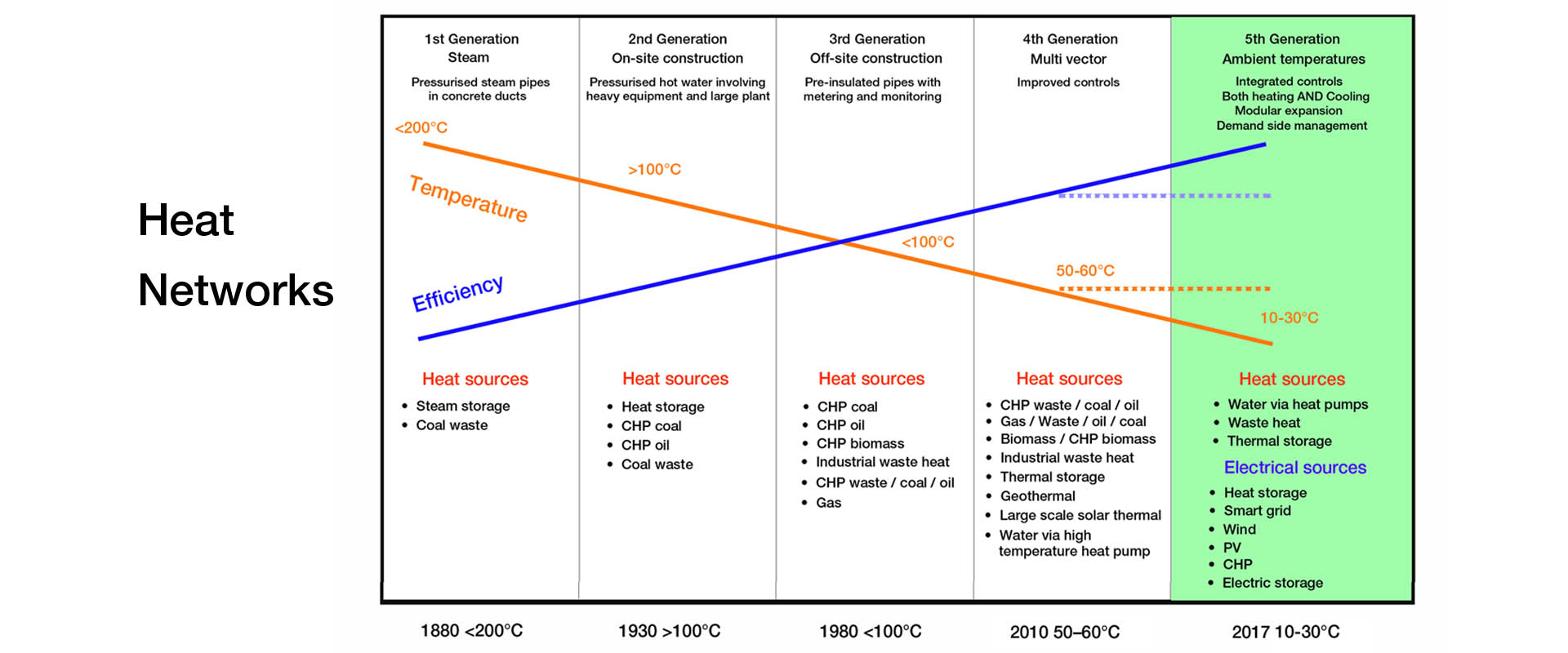

Since their steam-driven inception in the 1880s, heat networks have evolved.

That journey has largely been one of ever-diminishing network temperatures accompanied by increasing energy efficiencies.

As the following diagram shows, the 200oC pressurised and coal-produced steam of the 19th century gave way to pressurised hot water at around 100oC in the mid-1900s.

In the 1980s, we reached the third generation of heat pumps which made use of off-site construction and pre-insulated pipework. Network temperatures dropped to below 100oC. Many of these networks were built in response to the oil crises of the 1970s, so heat sources tended to be coal, biomass and heat generated from burning waste.

Fourth generation heat networks developed around 2010. Their average temperatures are closer to 70oC or lower. Heat sources continue to be CHP and biomass, but they also use gas boilers, biomass and large-scale heat pumps. New design and construction of third generation heat networks came to a halt some time ago, but there are many legacy systems on the market.

Current designs tend to focus on fourth generation types, but we are seeing a growing number of fifth generation heat networks being developed.

It is important to note the key differences between these generations because they highlight a step-change in network temperatures that is driving a significant increase in system efficiencies.

An evolution not a revolution

.

A shift to heat pumps

Older fourth generation heat networks have a centralised heat generation energy centre that supplies heat outwards to buildings (or to apartments in a communal heat network). Flow temperatures are between 55oC and 75oC, with a wider DeltaT and return temperatures at around 30oC to 40oC.

These heat networks typically supply heat interface units (HIUs) to generate domestic hot water and low temperature hot water for heating directly in the apartment. Cooling would be a separate system, and there is no interchange of heat between buildings or across buildings.

However, in more recent fourth generation heat networks we are seeing a shift away from the traditional fossil-fuel energy centre. These are replaced with heat pumps, which can be air-source or water-source depending on the availability of a nearby source such as rivers or waste energy.

CIBSE’s AM16: Heat pump installations for multi-unit residential buildings offers guidance on this approach and recommends a flow temperature of around 55oC.

Selection of specialist HIUs is required to ensure the system can deliver the required space heating and hot water requirements. Return temperatures should be approximately 30oC, and the addition of mixing valves ensures that return temperatures to the heat pumps are increased for efficient operation.

Distribution heat losses

Although fourth generation heat networks are more energy efficient than their predecessors, there are some problems related to their use.

Firstly, they are an outwardly-directed energy system, so there is no opportunity for heat recovery across the system. This means that any cooling in the building will dump rejected heat directly into the atmosphere rather than recovering and re-using it.

A second issue is with distribution heat losses. This was highlighted by BRE in a 2016 report. This showed much higher distribution loss factors (DLF) than expected: 1.5 rather than 1.05. While this may seem a small difference, it equates to a 33% distribution loss rather than a 5% loss.

The reasons given for these high losses included little, or intermittent, heating demand in new apartments yet water temperatures in pipes being maintained. Poor insulation of pipework and heat exchangers was also a source of losses, along with over-sized pipeworks.

A step-change to the future

These are some of the reasons we are seeing a growing focus on the next evolution of heat networks; a fifth generation.

The first key difference with this new approach is that network temperatures are much lower: between 10oC and 30oC.

And in place of an energy centre that pushes energy out into the network, there is an ambient energy loop. Water is pumped around the loop and used as a heat source or a heat sink by heat pumps in each building or apartment on the network.

To ensure that the loop maintains the correct temperature range, network balancing is introduced in the form of a heat pump.

Mixed loads in the same building

An example of the benefits of this approach is in a mixed-use building with apartments over some retail outlets and a gymnasium. The ambient loop runs throughout the building as a heat source or sink.

Heat pumps in each apartment provide space heating and hot water. A water-source VRF air conditioning unit uses the heat network as a heat sink to create cooling in the shops and gym.

The choice of technology will depend on the type of project and requirements for space heating, DHW and cooling.

However, the benefits of fifth generation heat networks are clear. They make the fullest use of heat pump technology and low operating temperatures also almost eliminate heat losses and contributions overheating in the building.

What’s more, ambient loops offer opportunities for heat recovery across the network, which provides the means to reduce primary energy consumption and increase efficiencies.

This is an important point for the UK on its journey to decarbonisation.

As we transition from fossil fuels to an electrified economy, we must find ways to reduce our primary energy consumption. By combining these two practical, well-established technologies in a novel way, engineers can help to evolve our approach to heating.

James Chaplen is Senior Product Manager for Mitsubishi Electric UK & Ireland